| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Qingdao Sande Tech Co.,Ltd

Model Number : OEM

Certification : ISO, DIN, AISI, ASTM, BS, JIS, etc.

Place of Origin : Qingdao, China

MOQ : 100pcs

Price : $0.5-2

Payment Terms : D/P,T/T,Western Union

Supply Ability : 10000PCS/month

Delivery Time : 30 days

Packaging Details : Wooden case

Casting Weight : 5g~100kg/per piece

Dimensions : depends on customer's requirements

Angle Tolerance : ±0.5°~±1°

Process : Machining

Surface : polish

Minimum Wall Thickness : 2mm(1mm for small area)

Means Of Transport : Sea transport

Drw Format : PDF/DWG/IGS/STP/ etc

Surface Roughness : Ra1.6-3.2

Packing : Wooden box

PRODUCT OVERVIEW

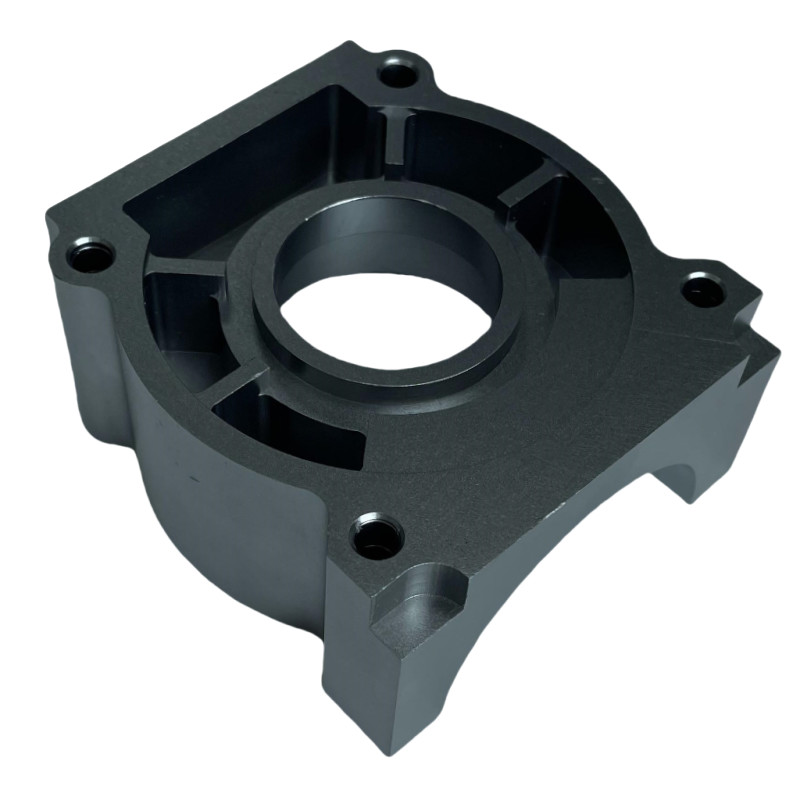

Our custom aluminum die-cast end caps are engineered for superior performance in demanding industrial environments. Manufactured using high-pressure die casting (HPDC) and finished with precision CNC machining, these components deliver exceptional dimensional accuracy, corrosion resistance, and lightweight durability for OEM applications.

KEY FEATURES & BENEFITS

✔ Premium Aluminum Alloys – A380, ADC12, or custom blends for optimal strength-to-weight ratio

✔ Precision Tolerances – CNC machined to ±0.05mm for leak-proof sealing surfaces

✔ Complex Geometries – Die casting enables intricate shapes with internal threads/knurls

✔ Surface Finishes – Anodized (Type II/III), powder-coated, or chromate conversion coated

✔ Rapid Prototyping – Supports low-volume batches to full production runs

TECHNICAL SPECIFICATIONS

Process : High-pressure die casting + secondary CNC machining

Wall Thickness : 1.5mm–12mm (design-dependent)

Size Range : 10mm–300mm diameter

Pressure Rating : Up to 450 PSI (with proper sealing design)

Temperature Resistance : -40°C to 200°C (alloy-dependent)

Certifications : ISO 9001, IATF 16949, RoHS compliant

TYPICAL APPLICATIONS

Hydraulic Systems : Pump/valve end covers

Electrical Enclosures : Waterproof cable glands

Automotive : Sensor housings, transmission covers

HVAC : Compressor end shields

Robotics : Actuator housings

FAQ:

1,What tolerances can you achieve with CNC machining?

Our CNC machining ensures tight tolerances of ±0.05mm (±0.002") for critical sealing surfaces. For ultra-precision applications, we can achieve ±0.02mm with post-machining processes.

Related Keywords:

"Precision CNC machining tolerances"

"High-accuracy die-cast end caps"

2,Can you accommodate custom designs or OEM specifications?

Yes! We specialize in custom OEM end caps with:

Threads (metric/UNF/NPT)

O-ring grooves

Embossed logos/part numbers

EMI/RFI shielding

Submit your CAD files (STEP, IGES) for a free DFM (Design for Manufacturing) review.

3,What surface finishes are available?

Choose from:

Anodizing (Type II/III for corrosion resistance)

Powder coating (color options available)

Chromate conversion (for electrical components)

As-machined (Ra 1.6μm)

|

|

Custom OEM Die Cast Aluminum End Cap Precision CNC Machined For Industrial Images |